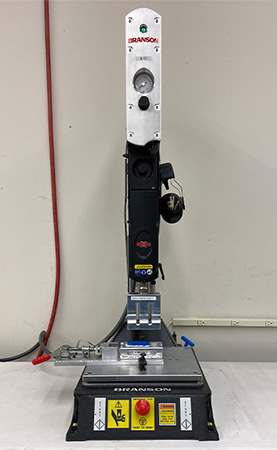

Ultrasonic Welding

The Technology

Ultrasonic welding utilizes high-frequency acoustic vibrations applied to materials held under pressure to create a high-integrity solid-state weld.

This advanced method is the industry standard for joining thermoplastics and similar materials. By creating a molecular bond, it eliminates the need for mechanical fasteners or chemical additives, ensuring a cleaner and more durable finish.

Key Advantages

Significant Cost Reduction

By eliminating the need for connective bolts, nails, soldering materials, or adhesives, you drastically reduce your bill of materials (BOM) and overall production costs.

Superior Aesthetic Finish

Create visually stunning products with seamless joints. Because there are no visible seams or external binding agents, the finished piece maintains a clean, premium appearance.

Optimized for Electronics

The perfect solution for delicate wires and circuitry. Our process creates reliable bonds without introducing thermal distortion or impurities, protecting the integrity of sensitive electrical components.

Rapid Production Speed

Instant Bonding: No solvents to dry and no cure time required.

Automation-Ready: Welding is triggered by a single lever or

button, enabling high-speed automated workflows.

Why Choose Ultrasonic Welding?

| Benefit | Impact on Your Project |

|---|---|

| No Consumables | Lower manufacturing costs & less waste. |

| No Thermal Distortion | Safe for high-precision electronics and circuitry. |

| Solid-State Weld | High-strength, reliable bonds every time. |

| Clean Process | No fumes, adhesives, or messy clean-up. |