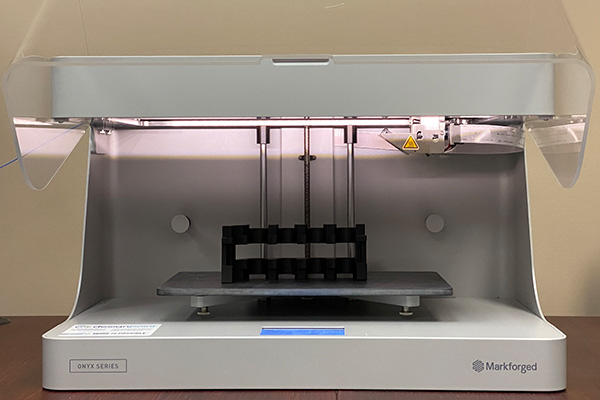

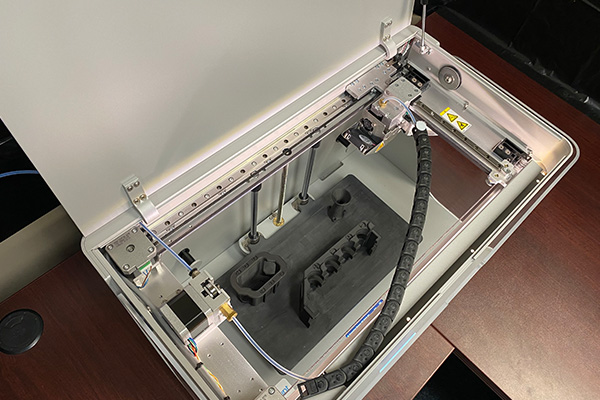

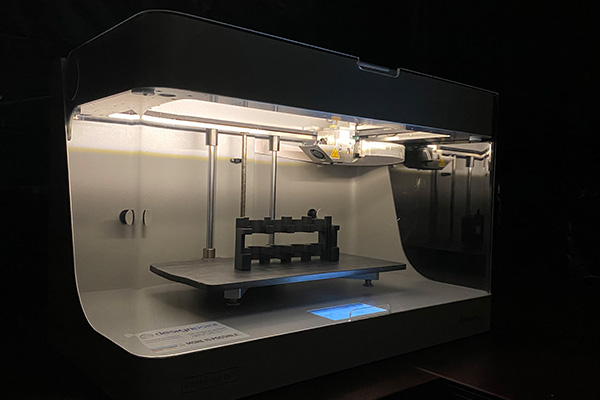

3D Printing & Rapid Prototyping

Why Choose Our Additive Manufacturing

- Rapid Iteration: Transform digital files into physical prototypes in hours, allowing for faster design cycles.

- Complex Geometries: Create intricate internal structures and custom battery enclosures that are impossible to achieve with traditional milling.

- Material Efficiency: Our additive processes reduce waste by utilizing only the precise amount of material required for each component.

Technical Specifications

- Technology: Industrial-grade FDM, SLA, and SLS printing.

- Materials: High-performance engineering plastics, resins, and composites.

- Primary Applications: Custom enclosures, internal spacers, functional prototypes, and assembly jigs.

The Process Integration

- Design Validation: 3D printing is utilized during Step 2 (Preliminary Design) to verify form and fit.

- Functional Testing: During Step 3 (Design & Development), 3D-printed parts are used for mechanical testing and thermal management validation.